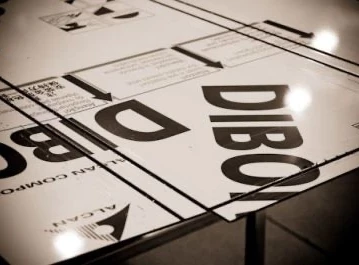

CNC Router Engraving

Platinum Signs has both laser cutting technology as well as CNC router engraving capability. Both are fantastic yet unique ways to engrave on materials.

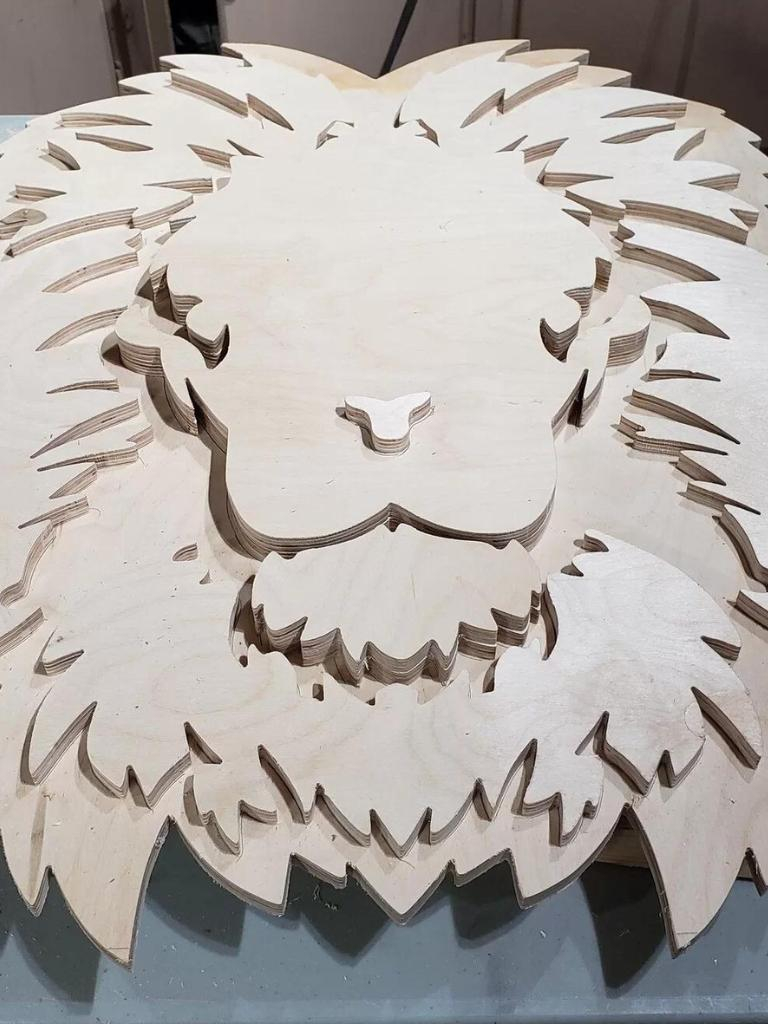

The main difference is the fineness of engraving with laser vs router. The laser is higher in precision vs the engraving tools for the router system. Thereafter for very detailed, intricate engraving, we use the laser and for deeper, thicker cuts or three-dimensional engraving, we mostly use the CNC router engraving bits.

When engraving plastic, we have a limited number of options such as acrylic that can be used,. Acrylic cuts can create toxic fumes when laser engraving is used. That is not a problem faced with the router system, as metal tools are used to drill, carve into the material instead of burning the surface. You can achieve considerable deeper cuts with the router.

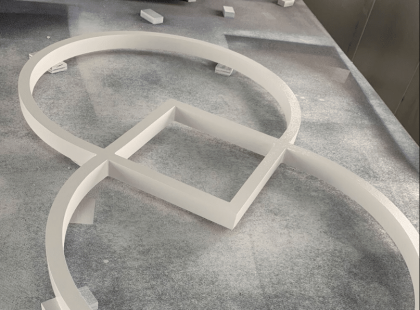

The CNC router engraving machine has a wide range of applications, and can be applied to various industries and fields, suitable for a large quantity of materials, such as thick wood and ACM composite panels which can be v grooved.

The CNC carving process can be applied to decoration, musical instruments, signs, furniture, cabinet making, souvenirs, a long list of materials such as plastics, foams, ABS, PVC, acrylic, marble, ACP / ACM panelling, pure aluminium, wood, plywood, MDF, copper and other soft metal materials.

CNC Router Cutting – Fast & Efficient

Ready to start your next project?

Get a Quote.Driving signage success across diverse sectors.

6500+

Completed Projects

We offer signage services for different industries. All in one solutions for signage industries. View more Industries

Our Clients